Supplier: Guangdong Test EQ Equipment co., Ltd.

Address: TESTEQ Science and Technology Park, No. 5, Wenzhou Road, Dongcheng Sub-district, Dongguan City, Guangdong Province, China

Country: China

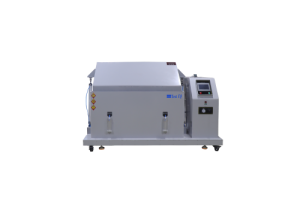

salt fog test chamber(Salt /Temperature /Humidity)

Price: 10000

介绍

循环腐蚀试验箱可以进行多种测试,包括:盐雾、加热和冷却、湿度、干燥。测试是可编程的。您可以根据需求设置测试程序。

除了普通盐雾试验机的功能外,它还结合了交变(循环)盐雾试验的功能,以提供诸如循环腐蚀和线状腐蚀的测试环境。它具有热风干燥、湿热、强制干燥和盐雾等测试环境。

主要测试项目适用于环境中有严重变化的物品,如:汽车零部件、航空设备、建筑材料、涂层电、电气机器等,结合盐雾、干燥、湿热和循环测试。如果您需要更多关于我们测试设备的型号,请参考我们的实验室测试(.)com

符合标准:

DO160 E/F/G 盐雾测试要求

GB/T 20854-2007/ISO14993-2001

金属和合金在盐雾、“干燥”和“湿”条件下暴露的腐蚀循环的加速测试

GB/T24195-2009/ISO 16151:2005 在酸盐雾、干燥和湿条件下进行的循环加速腐蚀测试

GJB 150.11A-2009 军事设备实验室环境试验方法盐雾试验

GB/T 2424.17-2008/IEC60068-2-11:1981 盐雾试验方法

GB/T 2423.18-2012/IEC 60068-2-52: 1996 氯化钠交替盐雾试验方法

GB/T 2423.3-2006/IEC6008-2-78-2001 试验箱:恒湿热试验方法

GB/T 10125-2012/ISO9227-2006 人造气氛盐雾试验中的腐蚀试验

GB/T 31467.3-2015

电动汽车用锂离子动力蓄电池组和系统

- 第3部分:安全要求和试验方法:盐雾试验

ASTM B117,ASTM B368

GB/T 10587-2006 盐雾试验室技术条件

GB/T 10586-2006 湿热试验室技术条件

GB/T 5170.8-2008_Test method for environmental test equipment for electrical and electronic products-salt spray test equipment

1.Structure of Salt Mist Test Chamber: with enclosure is a fully anti-corrosion structure, made of multi-layer fiberglass reinforced polyester resin, and constructed with corrosion-resistant materials.

2.Unique design: Large spraying area and high flow rate, resulting in shorter spraying time compared to fogging the solution under salt spray function.

3.Custom nozzle: Specific nozzles evenly spray the solution onto the test sample, and the solution flow rate can be adjusted.

4.The nozzle is installed on an independent module, making it easy to remove when fogging function is enabled.

5. 可编程触摸屏控制器允许使用中文和英文进行操作,并可进行数据收集。

6. 提供标准试样架,可容纳平板样品。对于超尺寸和重型三维样品(如汽车轮毂和发动机部件),可以使用与支撑高度相同的网格套件。外壳结构坚固,可均匀分布负载。

7. 喷雾时间和开关时间可以直接编程,以更好地控制腐蚀速率。

循环腐蚀试验箱可以进行多种测试,包括:盐雾、加热和冷却、湿度、干燥。测试是可编程的。您可以根据需求设置测试程序。

除了普通盐雾试验机的功能外,它还结合了交变(循环)盐雾试验的功能,以提供诸如循环腐蚀和线状腐蚀的测试环境。它具有热风干燥、湿热、强制干燥和盐雾等测试环境。

主要测试项目适用于环境中有严重变化的物品,如:汽车零部件、航空设备、建筑材料、涂层电、电气机器等,结合盐雾、干燥、湿热和循环测试。如果您需要更多关于我们测试设备的型号,请参考我们的实验室测试(.)com

符合标准:

DO160 E/F/G 盐雾测试要求

GB/T 20854-2007/ISO14993-2001

金属和合金在盐雾、“干燥”和“湿”条件下暴露的腐蚀循环的加速测试

GB/T24195-2009/ISO 16151:2005 在酸盐雾、干燥和湿条件下进行的循环加速腐蚀测试

GJB 150.11A-2009 军事设备实验室环境试验方法盐雾试验

GB/T 2424.17-2008/IEC60068-2-11:1981 盐雾试验方法

GB/T 2423.18-2012/IEC 60068-2-52: 1996 氯化钠交替盐雾试验方法

GB/T 2423.3-2006/IEC6008-2-78-2001 试验箱:恒湿热试验方法

GB/T 10125-2012/ISO9227-2006 人造气氛盐雾试验中的腐蚀试验

GB/T 31467.3-2015

电动汽车用锂离子动力蓄电池组和系统

- 第3部分:安全要求和试验方法:盐雾试验

ASTM B117,ASTM B368

GB/T 10587-2006 盐雾试验室技术条件

GB/T 10586-2006 湿热试验室技术条件

GB/T 5170.8-2008_Test method for environmental test equipment for electrical and electronic products-salt spray test equipment

1.Structure of Salt Mist Test Chamber: with enclosure is a fully anti-corrosion structure, made of multi-layer fiberglass reinforced polyester resin, and constructed with corrosion-resistant materials.

2.Unique design: Large spraying area and high flow rate, resulting in shorter spraying time compared to fogging the solution under salt spray function.

3.Custom nozzle: Specific nozzles evenly spray the solution onto the test sample, and the solution flow rate can be adjusted.

4.The nozzle is installed on an independent module, making it easy to remove when fogging function is enabled.

5. 可编程触摸屏控制器允许使用中文和英文进行操作,并可进行数据收集。

6. 提供标准试样架,可容纳平板样品。对于超尺寸和重型三维样品(如汽车轮毂和发动机部件),可以使用与支撑高度相同的网格套件。外壳结构坚固,可均匀分布负载。

7. 喷雾时间和开关时间可以直接编程,以更好地控制腐蚀速率。

SEND INQUIRY

Please fill in fully your information to send email

CATEGORY

Agriculture

Agriculture