Supplier: CHME Components Co., Ltd.

Address: No.17, An Fu Industrial District,Xingtan,Shunde

Country: China

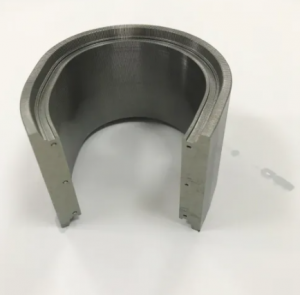

Bendable Limination

Price:

Bendable Limination

Product origin: guangdong

15 years OEM and ODM one-stop service, manufacturing all kinds of metal parts, ranging from precision metal parts to large sheet metal stamping parts, according to customer order quantity, we provide the most cost-effective way for your project, we Can use laser cutting, continuous progressive die automatic production.

Main Application: apply to Cryocoolers

Advantage

1. Specialized in manufacturing iron cores for 15 years, and exporting related components for more than 10 years

2. Obtained ISO9001, IATF16949 and other certifications

3. Short delivery time

4. Competitive price

5, Equipped with automatic powder spraying line

6. Welcome to customize orders

Our service

1. Have a strong R&D team

2. Quickly respond to your inquiries and feedback

3, good quality, strict quality control

4. Professional after-sales team

Related Products

visit our website:https://www.chmeindustry.com/other-lamination.html

Stator and rotor cores are essential components of an electric motor. The stator core is made up of thin layers of steel laminations, which are stacked and welded together. The lamination process is crucial as it significantly reduces the core's iron loss, which occurs due to the magnetic field's induction. The lamination of the core also reduces the Eddy current loss. Eddy currents are generated in planes perpendicular to the magnetic field, which can cause excessive heat generation and damage to the core. However, by laminating the core, the Eddy currents are limited, and the core's efficiency is enhanced. Welding is another crucial process in the manufacturing of stator and rotor cores.

Our company, CHME Components employs top-of-the-line machines and skilled craftsmanship to ensure the welding process is seamless and precise, resulting in a reliable and robust core. Our focus on lamination in welding ensures the cores we produce are efficient and durable, providing maximum performance for your electric motors.

Product origin: guangdong

15 years OEM and ODM one-stop service, manufacturing all kinds of metal parts, ranging from precision metal parts to large sheet metal stamping parts, according to customer order quantity, we provide the most cost-effective way for your project, we Can use laser cutting, continuous progressive die automatic production.

Describe | Custom stamped stator and rotor cores |

Types Of | Other lamination (other iron core) |

Application | Ultrasonic refrigeration device |

Processing | stamping |

Material | Silicon steel |

Weight Range | 0.5-100Kg |

Design Support | AutoCAD, Solidworks, PDF |

Quality Control | Materials, Dimensions, Properties, Internal Defects, Balance Tests |

Standard | ASTM, DIN, JIS, ISO, GB standard |

Main Application: apply to Cryocoolers

Advantage

1. Specialized in manufacturing iron cores for 15 years, and exporting related components for more than 10 years

2. Obtained ISO9001, IATF16949 and other certifications

3. Short delivery time

4. Competitive price

5, Equipped with automatic powder spraying line

6. Welcome to customize orders

Our service

1. Have a strong R&D team

2. Quickly respond to your inquiries and feedback

3, good quality, strict quality control

4. Professional after-sales team

Related Products

visit our website:https://www.chmeindustry.com/other-lamination.html

Stator and rotor cores are essential components of an electric motor. The stator core is made up of thin layers of steel laminations, which are stacked and welded together. The lamination process is crucial as it significantly reduces the core's iron loss, which occurs due to the magnetic field's induction. The lamination of the core also reduces the Eddy current loss. Eddy currents are generated in planes perpendicular to the magnetic field, which can cause excessive heat generation and damage to the core. However, by laminating the core, the Eddy currents are limited, and the core's efficiency is enhanced. Welding is another crucial process in the manufacturing of stator and rotor cores.

Our company, CHME Components employs top-of-the-line machines and skilled craftsmanship to ensure the welding process is seamless and precise, resulting in a reliable and robust core. Our focus on lamination in welding ensures the cores we produce are efficient and durable, providing maximum performance for your electric motors.

SEND INQUIRY

Please fill in fully your information to send email

CATEGORY

Agriculture

Agriculture