Supplier: Henan Doing Mechanical Equipment Co.,Ltd

Address: Room 1408, 14th Floor, Building 9, No.133 Yaozhai Road, Jinshui District, Zhengzhou City, Henan Provincea

Country: China

Pyrolysis plant manufacturers

Price: 48000$

Pyrolysis plant for recycling waste tyre/plastic

Doing as a produced pyrolysis plant manufacturers ,we can produced waste tyre /plastic/rubber pyrolysis plant with new desing and high quality ,the waste tyre/plastic/rubber pyrolysis plant can pyrolysis waste tyre/plastic/rubber to fuel oil ,carbon black and steel wire.

What is pyrolysis ?

Pyro = heat. Lysis = break down.Plastic Pyrolysis is chemical reaction. This reaction involves molecular breakdown of larger molecules into smaller molecules in presence of heat. Pyrolysis is also known as thermal cracking, cracking, thermolysis, depolymerization, etc.

Pyrolysis can be used to convert chemicals such as ethylene dichloride to polyvinyl chloride (PVC). Biomass or waste can be converted into other useful products such as syngas using pyrolysis.

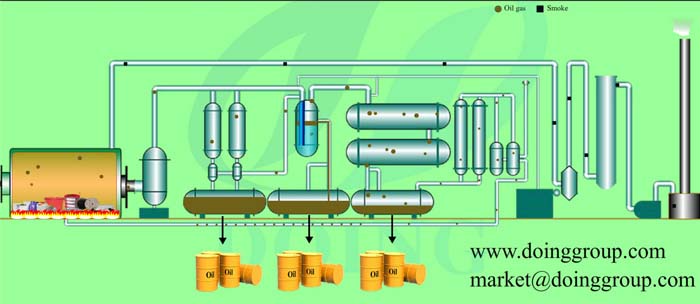

Pyrolysis plant process waste tyre/plastic/rubber to fuel oil

Pyrolysis plant process waste tyre/plastic/rubber to fuel oil

1.Feed raw materials

The raw material can be waste tyre/waste plastic/waste rubber. Always feed by the auto feeder.

2.Pyrolysis

Include a reactor and catalyst room. Heat the reactor by coal/wood/oil/natural gas. This part will produce high temperature oil gas, the oil gas then flow into the next system.

3. Condensing

Oil gas come out from the reactor and catalyst chamber then cooling down in this part. Condensing system include condenser pipe, oil water separator, horizontal condenser and waste gas condenser. This will make the oil yield to the maximum.

4.Waste gas recovery

This part mainly deal with the gas that cannot be condensed. The whole process is very steady and high efficiency.

5. Discharge

After finished oil produce, the temperature of reactor can be cooled down, When the temperature falls down to 40 degree then carbon black can be discharged automatically by the way of anticlockwise rotate the reactor. The carbon black will drop into slag pool and then use screw conveyor to clean the slag pool. After discharging the carbon black.

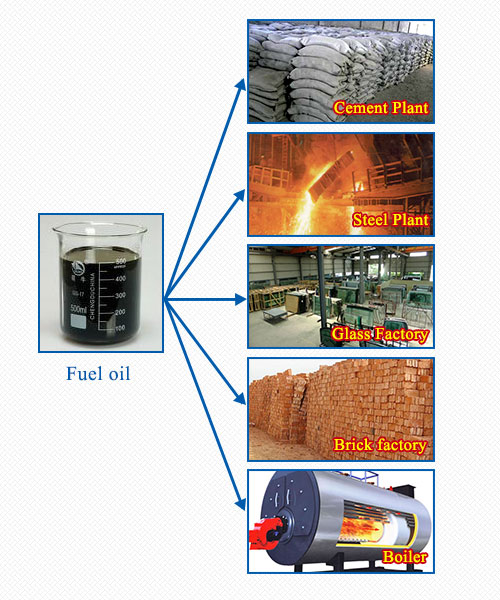

Fuel Oil (45% to 52%)

Fuel oil application

The main application of oil products produced by our pyrolysis plant is the fuel oil that is wide used for industrial and commercial purposes. Such as power plant factory,glass factory,cement factory,ceramic fatory.

Exhaust gas (About 10%)

We get about 10% pyrolytic gases during pyrolysis process. The main component of this gases are methane (CH4), so we can not condense and store this gases. We use this gases to heat the reactor and we can use exceed gases for other heating application.

Steel Wire (12% to 15%)

The third product of pyrolysis plant is steel wire, the quantity of steel wire is about 10% to 15% according to tyre quality. It is very easy to sell steel wire scrape in local market.

Carbon Black (30%)

Carbon black application

The second product of pyrolysis plant is carbon black. The quantity of carbon black is about 30% to 35% according to tyre quality. Carbon black can application to electric cable jacketing,black nylon bag,rubber additive

2.Turn plastic into oil machine

Turn plastic into oil machine is a new green pyrolysis technology for waste plastic recycling, which can be used for turning waste plastics into fuel oil and carbon black.

The turn plastic into oil machine is quite affordable and reasonable for the one who wants to start the plastic into oil busniness plan.

Contact: Ms Bonnie

Phone: +86-371-5677 1821

Mobile/Wechat/Whatsapp:0086-135-2669-2320

Skype: bonniezhao2

Email: oilmachine@doinggroup.com

http://www.wastetireoil.com

http://www.doinggroup.com

Chat online

SEND INQUIRY

Please fill in fully your information to send email

CATEGORY

Agriculture

Agriculture